Cleanrooms require routine testing, monitoring and certification to ensure that these controlled environments continue to perform in accordance with regulatory standards as detailed in ISO14644, EU GMP & EIST.

Lydair specialise in the testing, validation and certification of cleanrooms to procedures set out in ISO14644-3(2019).

Validation Services:

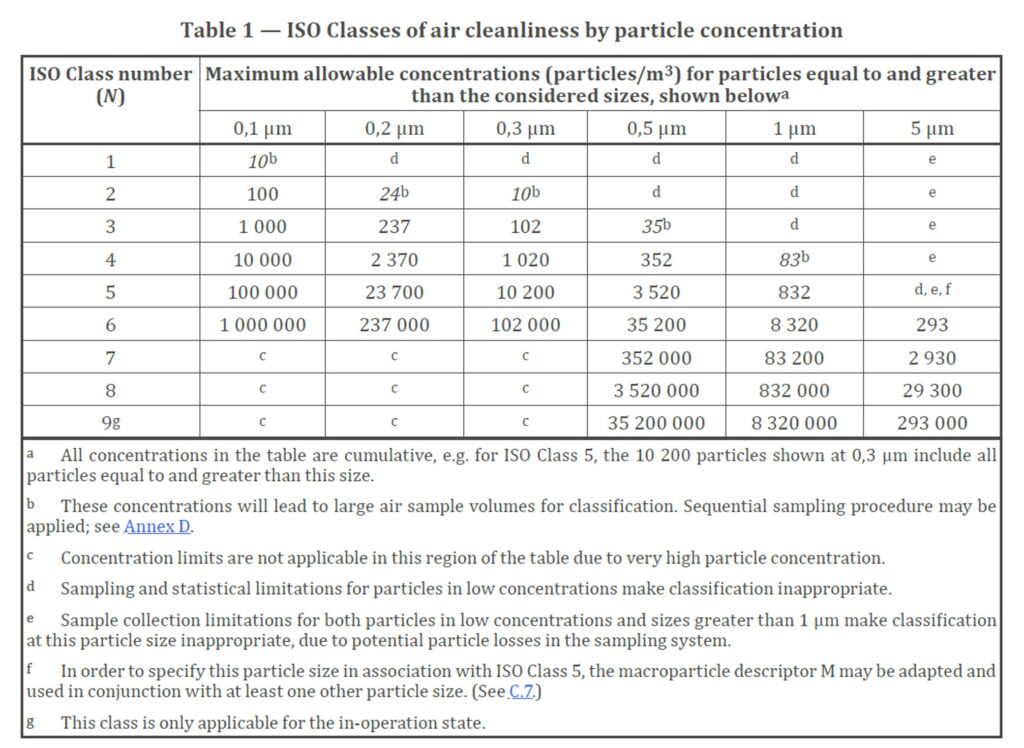

Airborne Particle Count

Measurement of airflow volume flow rates

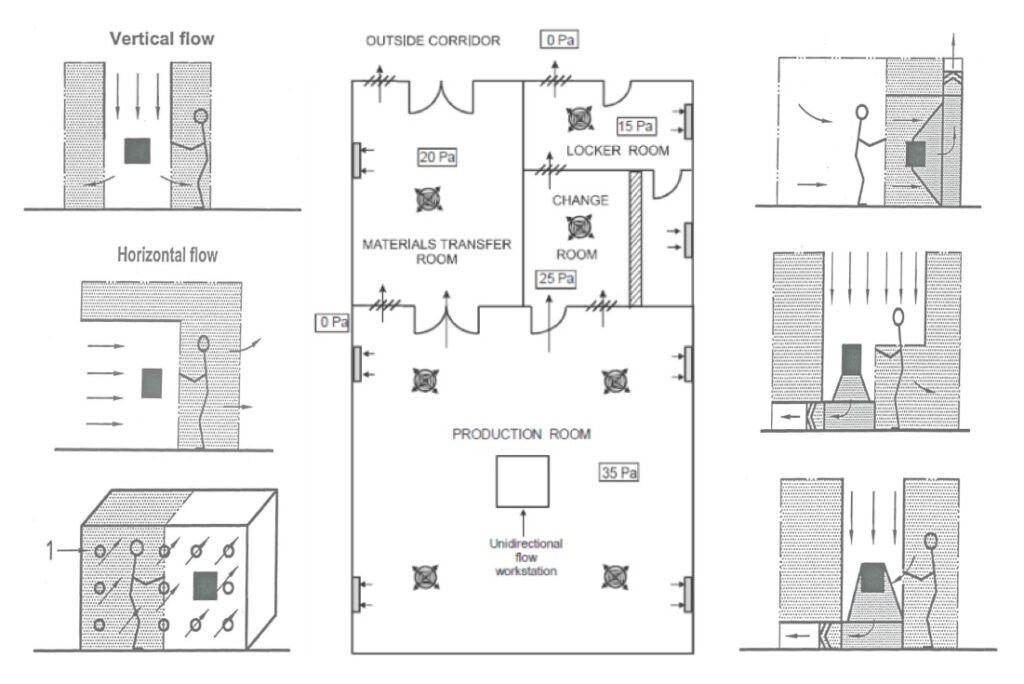

Measurement of static pressure differentials

Recovery times & recovery rates

Airflow pattern visualisation

HEPA filter integrity testing

Testing is conducted in accordance with ISO14644-1

Cleanrooms and associated controlled environments.

Part 1: Classification of air cleanliness by particle concentration

EU GMP Annex 1, and IEST.

Results being presented in a test report to ISO14644-1(2015)

Test procedures as ISO14644-3(2019) NA.1

Non-Viable Airborne Particle Counting

Establish the classification of the cleanroom environment by particle concentration as ISO14644-1(2015).

Supply Air Flow Rates

Cleanroom Validation requires the measurement of supply air flow rates and airflow velocities, in accordance with ISO14644-3 :2019. B2.2 & B2.3

At design stage, an estimated “in operation” particle generation and median ventilation coefficient are used to calculate the required volume flow rate as ISO14644-4:2024.

Room Pressures

ISO 14644-3:2019. B1.2

Cleanroom facilities utilise room pressure differentials as part of the air contamination control strategy.

Recovery time / Recovery Rates

A measured local recovery time/rate is a recommended method used to demonstrate effective air contamination control.

Evaluation by 10:1 or 100:1 recovery time

ISO 14644-3:2019. B4.3

Airflow Visualisation Testing

A smoke visualisation test is another recommended method used to demonstrate effective air contamination control.

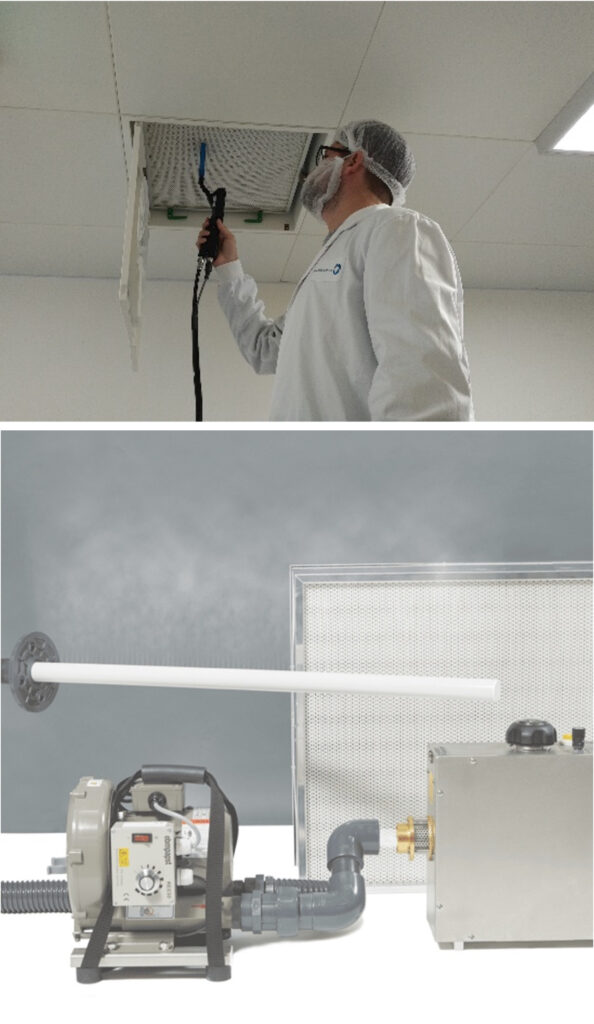

HEPA Filter Integrity Testing

In situ HEPA Filter Integrity Testing.

Method as detailed in ISO14644-3:2019 adapted from IEST-RP-CC034.4

The leak test establishes the level of leakage, relevant to the cleanliness performance of the installation.

Lydair offer two methods:

Aerosol photometer & Light-scattering airborne-particle counter (LSAPC)

Upstream aerosol challenge Ondina oil or monodisperse PSL.